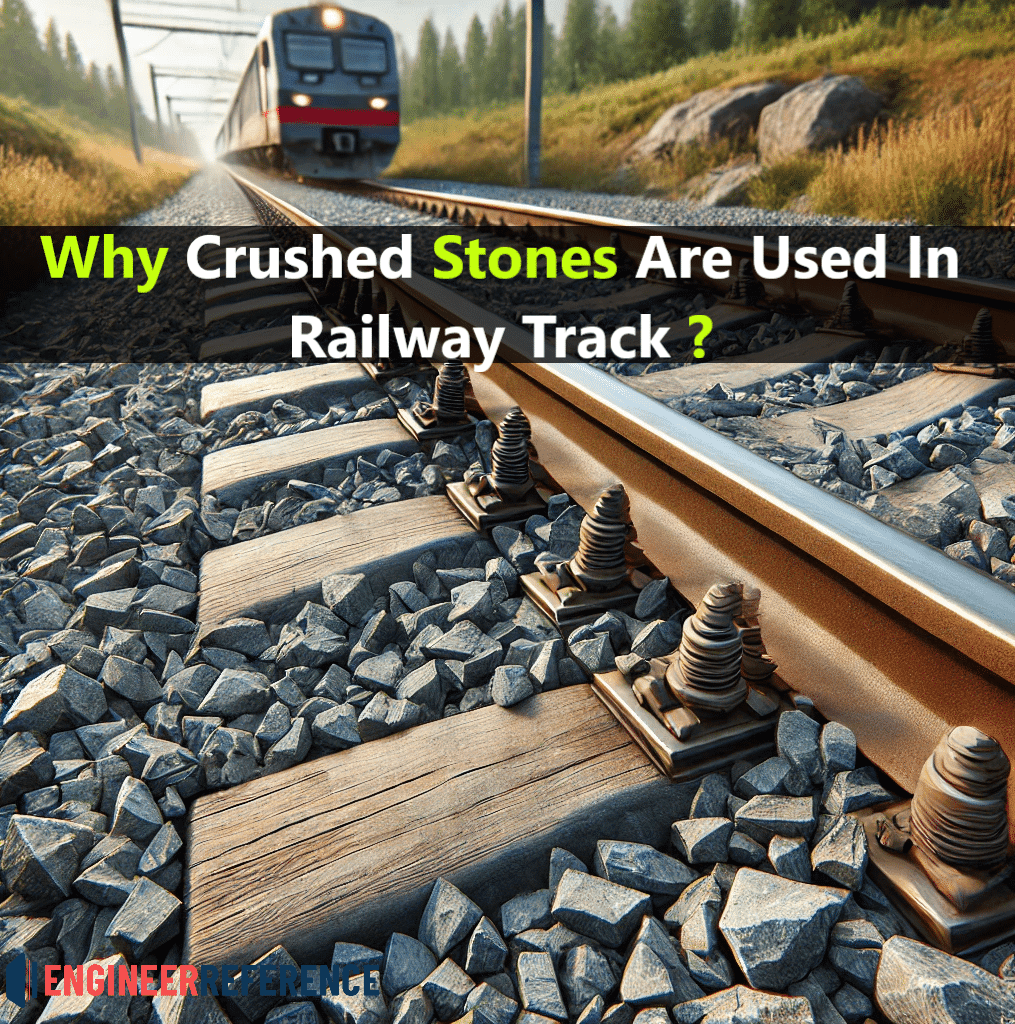

Why Crushed Stones Are Used in Railway Tracks?

Railway tracks form a crucial part of global transportation networks, and ensuring their longevity and stability is vital. The use of crushed stones, often referred to as “track ballast,” plays a significant role in maintaining the safety and functionality of railway lines. But why are crushed stones, or track ballast, used in railway tracks? Let’s delve deeper into the reasons behind their essential role.

What Are Crushed Stones in Railway Tracks?

Crushed stones, also known as ballast, are small, jagged rocks placed under and around railway tracks. These stones are not randomly selected but are specifically chosen for their durability and ability to withstand heavy loads and harsh weather conditions. Typically, materials like granite, trap rock, and limestone are preferred for this purpose. Their angular shapes allow them to lock together when placed under pressure, providing a stable foundation for the track.

1. The Function of Track Ballast

The primary function of track ballast is to bear the load transmitted by passing trains, distribute it evenly across the underlying foundation, and maintain the track’s position. Without the support of ballast, railway tracks would sink into the ground, leading to frequent maintenance and hazardous conditions. By distributing weight, track ballast keeps trains running smoothly.

2. Stability and Load Distribution

One of the critical reasons crushed stones are used is their ability to enhance the stability of railway tracks. Trains, particularly those carrying heavy cargo or traveling at high speeds, place enormous stress on the tracks. The weight needs to be evenly distributed to prevent the underlying soil from compressing or shifting, which can result in misalignments. Crushed stones effectively support this load, ensuring long-term track durability.

3. Drainage Efficiency

Water accumulation under railway tracks can lead to serious issues like corrosion, erosion, and track destabilization. Track ballast ensures efficient drainage by allowing rainwater and other moisture to flow through gaps between the stones, preventing water from collecting beneath the tracks. This helps in maintaining a dry, stable foundation, reducing the risk of structural damage over time.

4. Maintaining Track Geometry

Rail tracks must be geometrically aligned to allow for safe and smooth train travel. Misalignment, shifting, or sinking of tracks can lead to accidents like derailment. The angular design of crushed stones helps keep the railway track in place by locking together, thus maintaining its geometric configuration. This way, the track ballast helps ensure the rails remain perfectly positioned despite the heavy forces exerted on them.

5. Minimizing Vegetation Growth

An often-overlooked benefit of using crushed stones in railway tracks is their ability to prevent vegetation growth. Weeds and other plants can grow around the railway line, leading to root systems that destabilize the track structure. Since crushed stones do not allow for easy root penetration, they act as a natural deterrent to plant growth, keeping tracks clear and safe for train operation.

6. Absorbing Vibrations and Noise

Crushed stones are also excellent at absorbing vibrations and noise caused by passing trains. Without the ballast, vibrations would be transmitted directly to the ground, causing instability and excess noise pollution. By absorbing some of the vibration, the ballast helps protect the structural integrity of the railway line and reduces noise levels, which is particularly important in urban areas.

7. Enhancing Safety

Crushed stones play a direct role in enhancing the safety of railway systems. By stabilizing the tracks, preventing misalignments, and offering efficient drainage, track ballast reduces the likelihood of train derailments, one of the most dangerous accidents in railway travel. The ballast also protects the steel rails and wooden or concrete ties from excessive wear and tear, improving the lifespan of the track infrastructure.

8. Resisting Temperature Variations

Railway tracks experience significant temperature fluctuations, leading to expansion and contraction. Track ballast helps resist these temperature-induced stresses by providing a flexible yet stable foundation that accommodates thermal changes without damaging the rails or causing shifts. This is especially important in regions with extreme weather conditions where rapid temperature changes can affect the integrity of the railway system.

9. Easy Maintenance and Replacement

Another advantage of using crushed stones in railway tracks is their ease of maintenance and replacement. Unlike other track components that may require specialized tools or prolonged downtime for repairs, ballast can be quickly replenished or replaced as needed. Over time, the stones may become worn or displaced, but they are easily replenished without requiring the entire track to be removed.

10. Historical Use of Crushed Stones in Railways

The use of crushed stones as ballast has been a longstanding tradition in railway engineering. Historical records indicate that as early as the 19th century, engineers recognized the benefits of using stone ballast to stabilize tracks and improve performance. Over time, the materials and techniques have evolved, but the core principle of using crushed stones for track stability has remained unchanged.

11. Comparison to Alternatives

While modern alternatives like synthetic materials or prefabricated track systems exist, crushed stones remain the preferred choice for track ballast due to their cost-effectiveness, durability, and proven performance. These alternatives are typically more expensive and may not offer the same level of adaptability and drainage efficiency as traditional crushed stone ballast.

12. Environmental Impact of Using Crushed Stones

Despite their many benefits, the use of crushed stones in railway tracks is not without environmental consequences. Quarrying stone for ballast can lead to habitat destruction and increased carbon emissions. However, many railway companies are adopting more sustainable practices by using recycled materials or sourcing stones from environmentally responsible quarries.

13. Types of Crushed Stones Used

The most common types of crushed stones used in railway tracks are granite, trap rock, and limestone. Each type offers unique benefits in terms of hardness, durability, and drainage capabilities. Granite, for example, is highly durable and can withstand heavy loads, while limestone is more affordable and easier to quarry.

14. Cost-Effectiveness

Crushed stones are not only effective but also economical. Their long lifespan and ability to be reused or easily replaced make them a cost-effective solution for railway infrastructure. The use of natural materials like granite and limestone also means that the raw material is readily available, reducing overall costs.

15. Future Trends in Railway Track Ballast

While crushed stones are likely to remain a key component of railway tracks for the foreseeable future, research is ongoing into new materials and methods that may enhance ballast performance. Innovations such as composite materials, recycled rubber, and environmentally friendly solutions are being explored to make railway tracks even more durable and sustainable.

FAQs About Crushed Stones in Railway Tracks

1. What is the purpose of crushed stones in railway tracks?

Crushed stones, or track ballast, serve to stabilize the railway tracks, ensure efficient drainage, and distribute the weight of passing trains evenly across the foundation.

2. Can other materials replace crushed stones in railway tracks?

While alternatives like synthetic materials and recycled components exist, crushed stones are still preferred due to their proven stability, durability, and cost-effectiveness.

3. What types of stones are used in railway tracks?

Commonly used stones include granite, limestone, and trap rock. These stones are chosen for their hardness, durability, and ability to provide good drainage.

4. How do crushed stones prevent derailments?

By maintaining track geometry and providing a stable base, crushed stones help prevent the shifting of tracks, which could lead to derailments.

5. How often do crushed stones need to be replaced?

Track ballast may need to be replenished or replaced periodically depending on wear and environmental conditions, but they typically last for many years.

6. Do crushed stones have an environmental impact?

Yes, quarrying for crushed stones can have environmental consequences, but sustainable practices are being adopted to reduce these impacts.

Conclusion

Crushed stones are an integral part of railway infrastructure, providing essential support, drainage, and stability for tracks. Their ability to distribute weight, prevent water accumulation, and maintain track geometry makes them a key element in ensuring the safe and efficient operation of trains. While alternatives are being explored, crushed stones remain a proven and cost-effective solution for railway track maintenance and safety.

Related Topics

-

How to Determine the Right Septic Tank Size: Expert Guide with Key Factors

-

Why Bamboo is Stronger Than Steel Reinforcement: 7 Surprising Facts Revealed

-

The Ultimate Guide on How to Design a One-Way Slab | Expert Tips & Detailed Instructions

-

What Are the Main Components of a Bridge and Their Functions? | Complete Guide (2024)