What Are the Types of Culvert?

Culverts are essential structures used in transportation and water management systems, ensuring the smooth passage of water beneath roads, railways, and embankments. Their design helps prevent flooding, erosion, and infrastructure damage. But not all culverts are the same. This guide will take a deep dive into the different types of culverts, their materials, and their uses.

What is a Culvert?

A culvert is a structure that allows water to flow under a road, bridge, or similar obstruction. These conduits are typically made from materials like concrete, metal, or plastic, and they vary in shape and size depending on the specific application.

Why Are Culverts Important?

Culverts play a critical role in water management and infrastructure maintenance. They help prevent roads from washing away during heavy rains and direct streams and runoff safely beneath roads and paths. They also provide a pathway for animals and reduce erosion by managing water flow effectively.

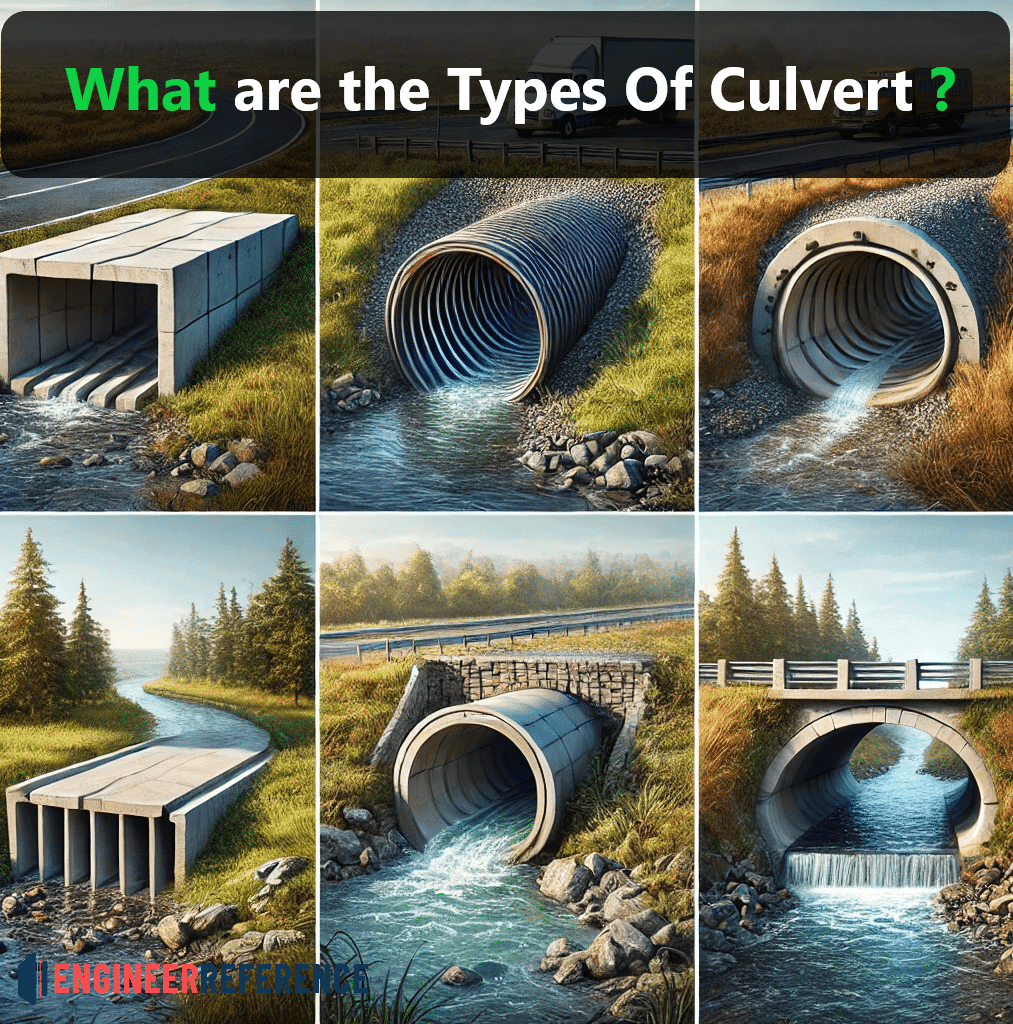

Common Types of Culverts

Culverts come in several shapes, sizes, and materials. The choice of the right culvert depends on factors such as the volume of water flow, site conditions, and intended use. Below are the most common types of culverts used today.

Pipe Culverts

Pipe culverts are the most commonly used type. They are circular in shape and can be made from various materials such as concrete, steel, or PVC. Pipe culverts are widely used due to their simplicity in design and installation.

Concrete Pipe Culverts

Concrete pipe culverts are known for their durability and strength. These culverts are ideal for heavy load applications, such as under highways and major roads. Their ability to withstand high pressures and resistance to environmental factors make them a popular choice in high-traffic areas.

Steel Pipe Culverts

Steel pipe culverts are lightweight, flexible, and strong. These culverts are often used in areas where high strength and resilience are needed, such as in locations with unstable soil. They are also resistant to corrosion when galvanized, but may require maintenance over time in highly corrosive environments.

PVC Pipe Culverts

PVC (Polyvinyl Chloride) pipe culverts are a cost-effective and lightweight alternative to steel and concrete. While they are not as strong, they offer excellent corrosion resistance and are easier to install. PVC culverts are often used in residential or low-traffic applications where water flow is moderate.

Box Culverts

Box culverts are rectangular structures commonly made from reinforced concrete. These culverts are especially suitable for areas with limited headroom or high-traffic locations. Box culverts offer high durability and can handle heavy loads, making them suitable for both pedestrian paths and roads. Their wide shape allows them to manage large water volumes and they are often used where space is limited.

Arch Culverts

Arch culverts have a curved structure that mimics a bridge’s arch. They are typically made of steel or concrete and are used in locations where aesthetics and environmental considerations are important. Their shape allows them to blend into natural surroundings, making them ideal for rural or scenic areas.

Slab Culverts

Slab culverts consist of a flat deck or slab that spans across the water path. They are generally used for smaller waterways and are typically made of concrete. These culverts are easy to construct and offer an affordable solution for minor crossings where the water flow is low to moderate.

Pipe-Arch Culverts

Pipe-arch culverts are a variation of standard pipe culverts but with a semi-circular or elliptical shape. This design is ideal for locations with shallow water flow or where traditional circular pipes would not fit. Pipe-arch culverts offer a wider flow area and are often used in areas where the vertical clearance is limited, such as beneath highways.

Factors to Consider When Choosing a Culvert

When selecting the appropriate culvert type, several factors should be considered:

- Hydraulic Capacity: The amount of water the culvert needs to handle.

- Load Bearing Requirements: The weight the culvert will support.

- Durability: The expected lifespan and resistance to environmental conditions.

- Material: The strength, flexibility, and maintenance needs of the culvert material.

- Site Conditions: Soil stability, water levels, and weather patterns.

How to Maintain Different Culvert Types?

Maintenance is essential for the long-term performance of culverts. Regular inspection is required to prevent clogging, erosion, or structural damage. Here are some general tips:

- Remove debris: Regularly clean the culvert to ensure water flows unobstructed.

- Check for corrosion: Metal culverts, particularly steel, may corrode and should be inspected for rust.

- Repair cracks: Concrete culverts may develop cracks over time, which should be sealed to maintain their integrity.

- Monitor water flow: Ensure that water is flowing properly and not causing erosion around the culvert.

Culvert Installation Process

Installing a culvert involves careful planning and execution. Here’s a simplified guide:

- Site Assessment: Evaluate the site and determine the correct culvert size and type.

- Excavation: Dig the area to prepare for culvert placement.

- Placement: Install the culvert at the proper elevation to ensure effective water flow.

- Backfill: Fill the area around the culvert with appropriate material to provide support.

- Compaction: Compact the backfill to avoid future settling and maintain structural integrity.

- Finishing: Add final surface materials, like gravel or asphalt, if needed.

Pros and Cons of Different Culvert Types

FAQs About Culvert Types

1. What is the most commonly used culvert?

Pipe culverts are the most widely used due to their ease of installation, cost-effectiveness, and versatility.

2. What material is best for culverts?

The choice depends on the application. Concrete is best for durability, steel for strength, and PVC for cost efficiency and corrosion resistance.

3. How do I know which culvert type is right for my project?

Consider factors like water flow, load requirements, and site conditions. Consulting with an engineer is often the best approach.

4. What is the lifespan of a culvert?

The lifespan of a culvert depends on the material. Concrete culverts can last over 75 years, while metal and PVC options typically last 30-50 years.

5. Can culverts be installed in urban areas?

Yes, culverts are essential in both urban and rural areas to manage water flow and prevent flooding.

6. How often should culverts be inspected?

Culverts should be inspected at least once a year, especially after major storms or heavy rainfall.

Conclusion

Choosing the right culvert is crucial for ensuring proper water management and infrastructure longevity. Each culvert type offers unique benefits depending on the location and requirements of the project. From the common pipe culverts to the more complex arch and box culverts, understanding these differences helps in making an informed decision.

Related Topics

-

10 Essential Types of RCC Beam You Should Know About in Construction

-

10 Essential Types of Joints in Concrete You Must Know (2024 Guide)

-

Maximum Bearing Capacity of Soil: Understanding, Factors, and Implications

-

The Definitive Guide to Understanding the Difference Between Primary, Secondary, and Tie Beams in Construction

-

Unveiling the Key Differences Between Development Length and Lap Length in Construction (2024 Guide)

-

Proven Method to Calculate Steel Quantity for RCC Beam, Column, and Slab (Step-by-Step Guide)